My Industry Partner Who Makes Tannins

Here's what happened:

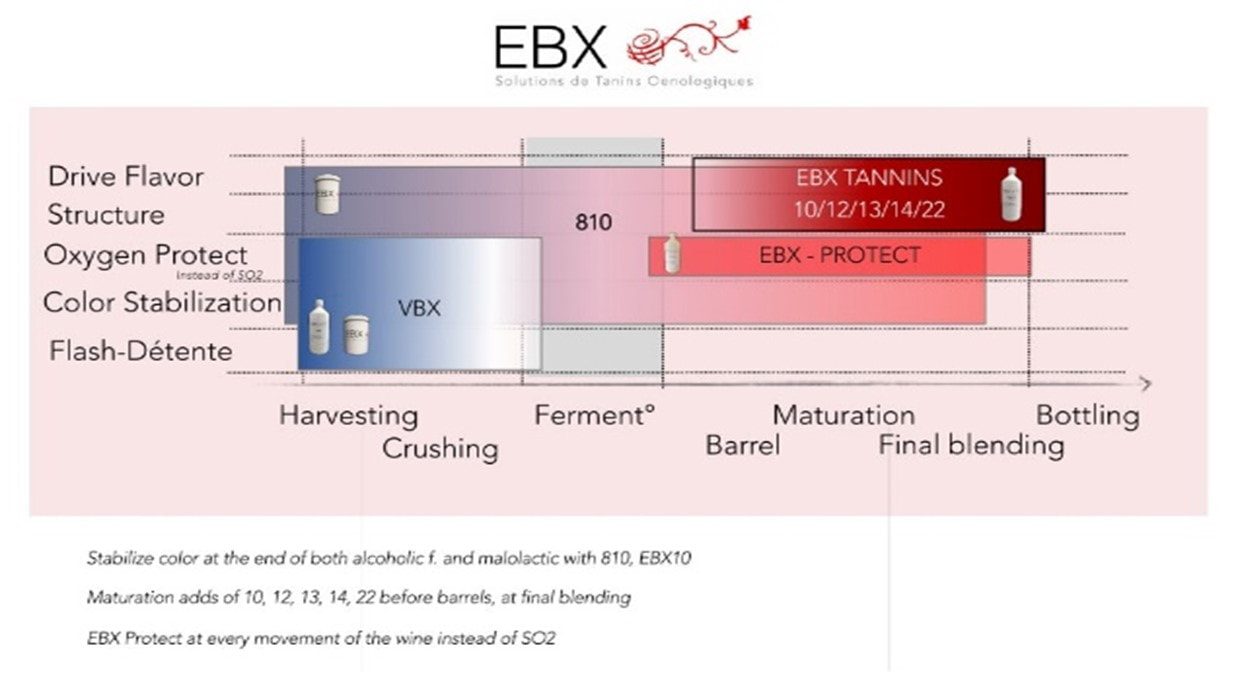

I asked Doug about timing on when we should start gently distributing information on our liquid tannins (pure oak extract) to help folks make a better "fast to market" wine. You see, I am trying to have a good seat when the post- harvest fray starts and everyone is scrambling for corks, etc. to get those less complex wines ready to pay some bills. I mean seriously! Our liquid tannins are going to be great for helping you keep color, clarity, aromas, etc. in the wines in queue for this next surge of bottling. You can add them two weeks before bottling.

So I email Doug asking for some timely info from a winemaker's perspective on what you should know on this topic before you order (something not as good) from a competitor.

Holy cow. This is what he sends:

from Doug Manning Consulting

In The Oxford Companion to Wine, Jancis Robinson describes oenological tannins as "commercial tannins produced by extraction of tannin from oak, chestnut, or birch woods and other suitable plant sources, including grape seeds."

Commercial enological tannins are approved wine additives, which have the generalized potential benefits to wine production:

- Provide protection to oxidation (antioxidant properties)

- Build body or mouthfeel

- Improve wine structure

- Stabilize wine color

- "Freshen" or "clean" wine mouthfeel/taste/aroma

- Develop mid-palate structure

- Improve wine flavor/aroma

- Reduce or mask undesired characteristics (e.g. green, reduced, etc.)

- Add depth to the wine's finish

- Enhance aging characteristics

https://pubmed.ncbi.nlm.nih.gov/23301601/

We worship the O.A.K. B.A.R.R.E.L.……..if it is from France (think EU) we prostrate ourselves (spelled that right, eh?) as the flavor and texture of the O. B. gives our fermented grapes a standard to which we aspire (angels singing here “ahhhhh…..)

So what is this about tannin that limits it to these tasks of repair and enhancement?

- Many types of wood products are used to make enological tannin

- They are toasted and S.O.L.D. by the K.I.L.O.G.R.A.M………..so as a tannin producer I want the most from my € ………so I B.O.I.L. => C.O.O.K. the wood to get everything I can from material……or I use alcohol to E.X.T.R.A.C.T. everything from the wood(s)

Here is the deal…..the O.B. imparts a rather narrow range of flavors and aroma into the wine. Remember you are adding an alcohol solution at a certain pH range and temperature for a certain amount of time

Again: ALCOHOL pH TEMPERATURE TIME

N.O.W. compare this extraction process of barrel aging to 2) above

[We are not cooking our wine, we control the pH between 3 – 4, we work at cellar temperature, we take our time]

N.O.W. perhaps our understanding of tannin can

Elevator Pitch 1st Floor

EBX Tannins are produced by soaking only aged French and American Oak in cold RO water, extracting the flavors and aromas you would expect from filling a barrel with wine and waiting. An oak extract from French or American Oak.

2nd Floor

Age your wines in a barrel, wait 6 – 12 – 18 months, finish and bottle.

Add oak alternatives to your beverage and wait 6 weeks (chips), 4 months (7mm staves), then finish and bottle.

Add EBX Tannin to your wine and wait 2 – 4 weeks, finish and bottle.

Closing

Are these processes identical? Nope

Are they close and acceptable for most types of wines? Yup

Are they cost effective and worth a try? (Oh Yes)